Melting and Casting

Steel and alloying metals are loaded into an electric arc furnace. Once in the furnace, the metal is heated to a specific temperature above its melting point, usually in excess of 2800°F.

What is Stainless Steel 316Ti, and what are its main properties?

Stainless Steel 316Ti Bars, Rods, Wires is a stainless steel variant belonging to the austenitic family, known for its excellent corrosion resistance and high-temperature strength. The "Ti" in 316Ti refers to adding titanium as a stabilizing element. This addition helps to prevent sensitization of the steel, which is a process that can occur during exposure to high temperatures, leading to the formation of chromium carbides and subsequent corrosion susceptibility. The main properties of Stainless Steel 316Ti include its exceptional resistance to corrosion in various environments, including acids, alkalis, and chloride-rich atmospheres.

Table Of Content

What are the applications of Stainless Steel 316Ti Bars, Rods, and Wires?

Stainless Steel 316Ti Bars find a wide range of applications across various industries due to their unique properties and versatility. The bars are commonly used in industries requiring excellent corrosion, high strength, and temperature resistance. One prominent application is in the chemical processing industry, where 316Ti bars are utilized to construct tanks, pipelines, and fittings handling corrosive chemicals and acids. Stainless Steel 316Ti Bars are favoured in the pharmaceutical industry for their hygienic properties and resistance to pitting and crevice corrosion.

Stainless Steel 316Ti Rods are extensively utilized in various applications across multiple industries owing to their exceptional properties and versatility. These rods are particularly favoured in industries that require excellent corrosion resistance, high strength, and reliability. In the construction industry, Stainless Steel 316Ti Rods find applications in structural components, architectural features, and building facades due to their superior corrosion resistance, ensuring durability and longevity in various atmospheric conditions.

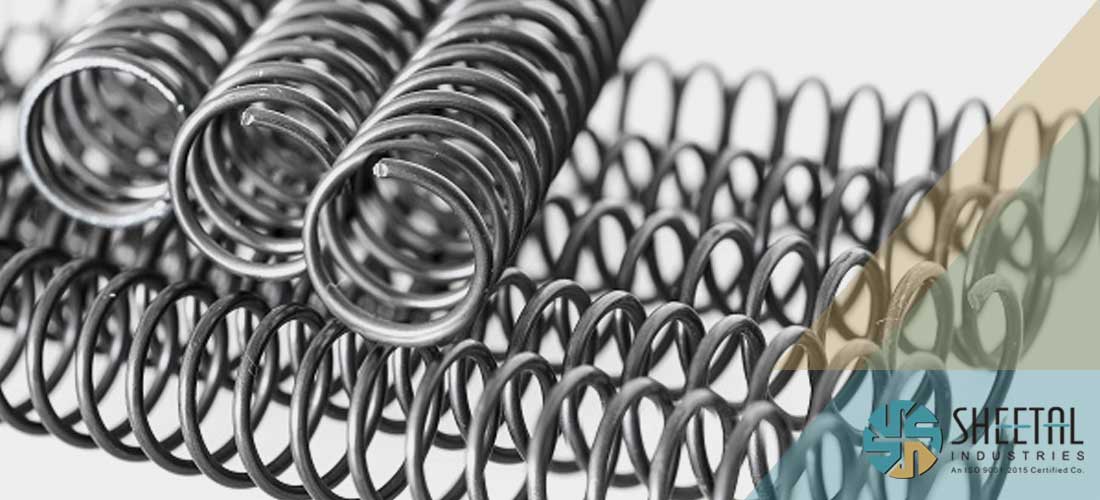

Stainless Steel 316Ti Wires offer numerous applications in numerous industries thanks to their unique characteristics and versatility. These wires are particularly valued in industries that demand excellent corrosion resistance, high tensile strength, and reliable performance. In the aerospace and aviation sectors, Stainless Steel 316Ti Wires find applications in manufacturing aircraft components, such as control cables, springs, and fasteners. The wires' corrosion resistance and strength ensure their durability and reliability in demanding aerospace environments.

| SS Bar Wire Standard | ASTM A276 / A479, ASME SA276 / A479 ASTM A580 ASME SA580 / ASTM A313 ASME SA313, AMS 5514 |

| Stainless Steel Bar Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Stainless Steel Round bar size | Diameter: 3-~800mm |

| Stainless Steel Hex Bar size | 2-100mm A/F |

| SS Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Stainless Steel Square bar size | 4 to 100mm |

| SS Wire Length | Cut Lengths: 0.125" to 72" No Limit on Spooled Lengths |

| SS Wires Diameter | 0.0004" to 0.040" 10 microns to 1.0 mm Other Sizes on Request |

| Wire Condition | M, Y, 1/2Hard |

| SS Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| SS Rectangular Bars Section | 3.0 to 12.0mm thickness |

| ASTM A276 Type Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| SS Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Stainless Steel Rectangular Size | 33 x 30mm to 295 x 1066mm |

| SS Hex Bars Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| ASTM A276 SS Type Hollow Bar Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| T-Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Tempers | Tempers range from dead soft annealed to ultra spring temper |

| Rolled Stainless Steel Flat Bars Condition | Hardened & tempered, annealed |

| ASTM A276 Type Cold Rolled Bar Technique | Stainless Steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Stainless Steel Rounds Bar Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Wire available in form of | Flat, Coil, mesh, Knitted wire mesh, spring, stranded and twisted |

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 410 | 1.4006 | S41000 | SUS 410 | X12Cr13 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Ti |

| SS 410 | 0.15 | 1.00 | 1.00 | 0.040 | 0.030 | 11.5 – 13.5 | - | 0.75 | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.74 g/cm3 | 1480 °C (2790 °F) | Psi – 74000 , MPa – 510 | Psi – 42000 , MPa – 290 | 34 % |

Ask Free Sample of SS 410 Bars, Rods, Wires Please Call On +91 9594327775 Or Mail Us On [email protected]

Contact Us