Melting and Casting

Steel and alloying metals are loaded into an electric arc furnace. Once in the furnace, the metal is heated to a specific temperature above its melting point, usually in excess of 2800°F.

How does Alloy Steel F11 compare to other grades of alloy steel?

Alloy Steel Grade 11 stands out among alloy steel grades due to its exceptional properties and characteristics. Its high strength and excellent corrosion resistance offers a reliable and durable option for various applications. Compared to other grades, Alloy Steel Grade 11 demonstrates remarkable toughness and resistance to wear, making it suitable for demanding environments and heavy-duty industries. Its enhanced resistance to oxidation and scaling at elevated temperatures further adds to its versatility. Additionally, Alloy Steel Grade 11 exhibits good weldability and formability, enabling easy fabrication and customization. These qualities make Alloy Steel Grade 11 a preferred choice for applications where strength, corrosion resistance, and reliability are essential factors.

Table Of Content

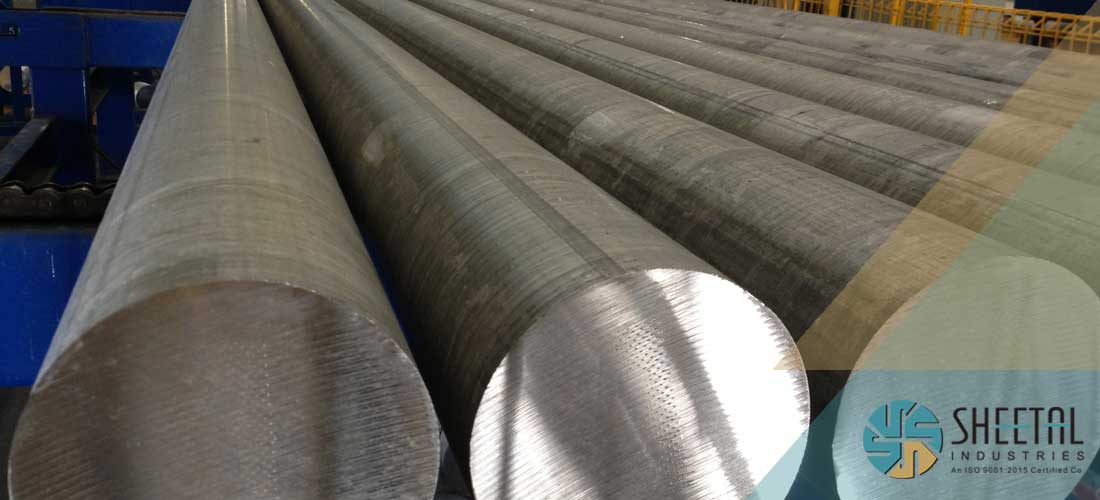

What are the key properties and characteristics of Alloy Steel Grade 11 bars, rods, and wires?

Alloy Steel Grade 11 bars possess several key properties and characteristics that make them highly sought after in various industries. These bars exhibit excellent strength and toughness, providing the ability to withstand heavy loads and resist deformation under high-stress conditions. Alloy Steel Grade 11 bars also offer impressive corrosion resistance, making them suitable for applications in corrosive environments. They also demonstrate good wear resistance, enabling them to withstand abrasive conditions and extend their service life.

Alloy Steel Grade 11 rods possess key properties and characteristics that make them highly desirable in various applications. These rods exhibit exceptional strength and toughness, enabling them to withstand heavy loads and resist deformation under demanding conditions. With excellent corrosion resistance, Alloy Steel Grade 11 rods are well-suited for use in corrosive environments, making them reliable for applications where protection against rust and degradation is crucial.

Alloy Steel Grade 11 wires are well-suited for corrosive environments, ensuring long-lasting durability and reliability. Moreover, these wires offer flexibility, allowing easy shaping and forming without compromising their structural integrity. Alloy Steel Grade 11 wires also exhibit remarkable high-temperature stability, making them suitable for applications where heat resistance is essential. Additionally, these wires demonstrate good electrical conductivity, making them ideal for use in electrical and electronic components.

| Standard | ASTM A182 / ASME SA182 |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | Diameter: 3-~800mm |

| Hex Bar size | 2-100mm A/F |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square bar size | 4 to 100mm |

| Wire Length | Cut Lengths: 0.125" to 72" No Limit on Spooled Lengths |

| Wires Diameter | 0.0004" to 0.040" 10 microns to 1.0 mm Other Sizes on Request |

| Wire Condition | M, Y, 1/2Hard |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangular Size | 33 x 30mm to 295 x 1066mm |

| Hex Bars Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Hollow Bar Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| T-Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Tempers | Tempers range from dead soft annealed to ultra spring temper |

| Condition | Hardened & tempered, annealed |

| Cold Rolled Bar Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Wire available in form of | Flat, Coil, mesh, Knitted wire mesh, spring, stranded and twisted |

| STANDARD | WERKSTOFF NR. | UNS |

| Alloy Steel F11 | 1.7335 | K11597 |

| Grade | C | Mn | Si | Mo | P | Cr |

| Alloy Steel F11 | 0.10 - 0.20 | 0.40 - 0.65 | 0.50 - 0.80 | 0.44 - 0.65 | 0.025 | 1.00 - 1.50 |

| Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min |

| 570 | 23 | 295 |

Ask Free Sample of Alloy Steel F11 Bars, Rods, Wires Please Call On +91 9594327775 Or Mail Us On [email protected]

Contact Us