Alloy Steel F9 Flanges are

essential components in various industrial applications where high-temperature and

high-pressure conditions prevail. These flanges are known for their exceptional strength,

corrosion resistance, and durability, making them an excellent choice for demanding

environments.

Composition and Properties: Alloy Steel F9 is a chromium-molybdenum alloy

that exhibits remarkable mechanical properties. It contains significant amounts of chromium

and molybdenum, which enhance its corrosion resistance and high-temperature strength. The

alloy is also known for its excellent tensile and yield strength, making it suitable for

various heavy-duty applications.

High-Temperature Performance: One of the primary advantages of Alloy Steel

F9 flanges is their exceptional performance at high temperatures. They can withstand

elevated temperatures and are often used in applications such as power generation,

petrochemical, and chemical processing, where heat resistance is critical.

Corrosion Resistance: Alloy Steel F9 has excellent corrosion resistance,

particularly in aggressive environments. This property is crucial in industries where

exposure to chemicals and corrosive substances is common. The flanges can resist the

damaging effects of chemicals, ensuring long-term reliability.

Versatility: These flanges are versatile and can be used in a wide range of

applications, including pipelines, pressure vessels, and boilers. Their adaptability is a

significant advantage for industries that require various flange types to meet specific

needs.

Durability: Alloy Steel F9 flanges are highly durable and have a long

service life, reducing maintenance costs and downtime. Their robust construction ensures

they can endure harsh working conditions and continue to perform reliably.

Quality Standards: Manufacturers of Alloy Steel F9 flanges adhere to

stringent quality standards, ensuring that these components meet industry requirements.

These standards guarantee the flanges' reliability and safety in critical applications.

Cost-Effective Solution: While Alloy Steel F9 flanges may have a higher

initial cost compared to some other materials, their long-term cost-effectiveness makes them

a preferred choice. Their durability and resistance to wear and tear reduce the need for

frequent replacements and maintenance.

Manufacturing Process Of Alloy Steel F9 Flanges

Raw Material Selection

The manufacturing process of flanges begins with the careful selection of

raw materials.

Cutting and Shaping

Once the raw materials are selected, they undergo a precise cutting and

shaping process.

Finishings and Coatings

Coating the materials to a specific temperature ensures they become

malleable, facilitating the shaping process.

Welding and Joining

These processes ensure secure and leak-proof connections, enhancing the

reliability and longevity.

Finishing and Quality Control

After this the buttweld fittings undergo comprehensive finishing and

quality control procedures.

Packaging and Delivery

To reach their destination in pristine condition, we employ careful

packaging techniques.

Specification Of Alloy Steel F9 Flanges

| Standard |

ASTM A181 / ASME SA181 |

| Dimension |

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092,

DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST

Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220,

BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flanges Size |

1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Flange Face Type |

Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female

(LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large

Tongue & Groove, Groove |

| Pressure Class |

PN 2.5 TO PN 400 |

| Pressure Rating ANSI |

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN |

6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Table |

D, E, F, H |

| Types |

Forged / Threaded / Screwed / Plate |

| Form |

Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank

Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange,

Lapped Pipe End Flange. |

| Flanges Marking |

All Flanges are marked as follows: Grade, Standard, Thickness, Heat No. (Or

according to the customer’s request.) |

Alloy Steel F9 Flanges Equivalent Grades

| STANDARD |

WERKSTOFF NR. |

UNS |

| Alloy Steel Gr 9 |

1.7386 |

K90941 |

Chemical Composition of Alloy Steel F9 Flanges

| Grade |

C |

Mn |

Si |

Mo |

Cr |

P |

Others |

| Alloy Steel Gr 9 |

0.15 Max |

0.30 - 0.60 |

0.50 - 1.00 |

0.90 - 1.10 |

8.0 - 10.0 |

0.030 |

- |

Mechanical Properties of Chrome Moly F9 Flanges

| Tensile Strength (ksi) min |

Elongation (% in 50mm) min |

Yield Strength 0.2% Proof (ksi) min |

| 415 |

30 |

205 |

Types Of Alloy Steel F9 Flanges

Alloy Steel F9 Slip-On Flanges

Alloy Steel Gr F9 Weld Neck Flanges

Chrome Moly Grade F9 Blind Flange

Alloy Steel F9 Socket Weld Flange

CrMo F9 Ring Type Joint Flange

Alloy Steel F9 Threaded Flanges

Alloy Steel Grade F9 Forged Flange

Alloy Steel F9 Lap Joint Flange

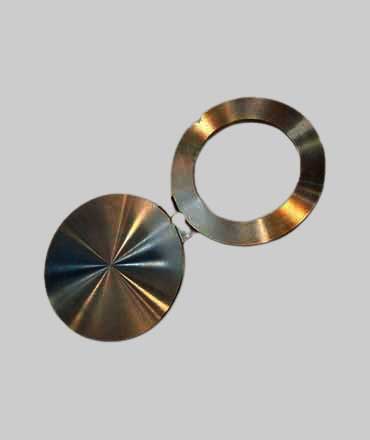

Alloy Steel F9 Spectacle Blind Flange

UNS K90941 Reducing Flanges

High Pressure Steel Gr F9 Square Flanges

Alloy Steel F9 Flat Face Flange

Other Types Of Alloy Steel F9 Flanges

- Alloy Steel F9 Pipe Flanges

- Alloy Steel F9 Spectacle Blind Flanges

- High Pressure Steel Gr F9 Slip On Flanges

- ASTM A181 Alloy Steel F9 Ring Type Joint Flanges

- CrMo F9 Lap Joint Flanges

- Chrome Moly F9 Tongue & Groove Flanges

- Alloy Steel F9 Socket Weld Flanges

- Alloy Steel Grade F9 Weld Neck Flanges

- Alloy Steel Gr.F9 Plate Flanges

- CrMo F9 Forged Flanges

- Alloy Steel F9 Loose Flanges

- UNS K90941 Threaded Flanges

- 1.7386 Reducing Flanges

- Chrome Moly F9 Long Weld Neck Flanges

- Alloy Steel F9 Blind Flanges

- Alloy Steel F9 Ring Type Joint Flanges

- ASME B16.5 Alloy Steel F9 BLRF Flanges

- Alloy Steel F9 Spectacle Blind Flanges

- CrMo F9 SWRF Flange

- ASME SA181 Alloy Steel F9 Nipoflange

- Alloy Steel F9 RTJ Flanges

- ASTM A181 Alloy Steel Grade F9 Flat Face Flanges

- UNS K90941 Screwed Flanges

- Alloy Steel Gr.F9 Slip on Flanges

- Chrome Moly Gr F9 PN 10 Flange

- 1.7386 Blind Flange

- Chrome Moly F9 Socket weld Flanges

- High Pressure Steel F9 Male & Female Flanges

- Alloy Steel F9 Welding Neck Flange

- CrMo F9 SORF Flanges

UNS K90941 Flanges Price, Dimension, Weight

Alloy Steel F9 Flanges Industrial Application

Power Generation Industry

Export & Supply Destination of Alloy Steel Gr.F9 Flanges

-

Europe

-

Asia & Middle East

-

Africa

-

America

-

Oceania

- Countries - France, United Kingdom, Slovakia, Turkey,

Malta, Estonia, Czechia/Czech Republic, Spain, Russia,

Ireland, Poland, Finland, Sweden, Portugal, Switzerland,

Cyprus, Hungary, Belarus, Serbia, Denmark, Norway,

Luxembourg, Azerbaijan, Ukraine, Italy, Lithuania,

Netherlands, Croatia, Greece, Romania, Monaco, Latvia,

Liechtenstein, Moldova, Germany, Belgium, Austria, Bulgaria.

- Cities - Bratislava, Helsinki, Murcia, Galați, Essen,

Poznań, Mannheim, The Hague, Las Palmas, Munich, Espoo,

Lublin, Antwerp, Palma de Mallorca, Athens, Riga, Dortmund,

Frankfurt am Main, Kaunas, Seville, Gdańsk, Barcelona,

Dresden, Bremen, Hanover, Berlin, Marseille, Bochum, Lisbon,

Zagreb, Stockholm, Varna, Amsterdam, Vila Nova de Gaia,

Dublin, Plovdiv, Bologna, Rotterdam, Sintra, Aarhus,

Thessaloniki, Münster, Sofia, Utrecht, Madrid, Szczecin,

Kraków, Vienna, Gothenburg, Alicante, Bucharest, Augsburg,

Malmö, Łódź, Prague, imișoara, Paris, Duisburg, Iași,

Wuppertal, Karlsruhe, Bydgoszcz, Milan, Nice, Leipzig,

Tallinn, Bonn, Zaragoza, Nantes, Toulouse, Brno, Budapest,

Cluj-Napoca, Lyon, Vilnius, Córdoba, Florence, Málaga,

Bielefeld, Düsseldorf, Warsaw, Copenhagen, Naples, Palermo,

Constanța, Nuremberg, Bilbao, Hamburg, Cologne, Turin,

Genoa, Wrocław, Bari, Stuttgart, Rome, Valencia.

- Countries - North Korea, Taiwan, Egypt, Japan,

Thailand, South Korea, Maldives, Armenia, Afghanistan, Iran,

Oman, Turkey, Sri Lanka, British, Azerbaijan, Nepal, China,

Hong Kong, Qatar, Iraq, Israel, India, Mongolia, Vietnam,

Russia, Kuwait, Lebanon, Kyrgyzstan, Philippines,

Bangladesh, Myanmar, Bhutan, Indonesia, United Arab

Emirates, Saudi Arabia, Jordan, Malaysia, Singapore,

Bahrain, Macau.

- Cities - Surabaya, Yangon, Pyongyang, Kabul, Sapporo,

Yerevan, Changsha, Baghdad, Peshawar, Hyderabad, Beijing,

Tainan, Tbilisi, Guangzhou, Kobe, Jaipur, Nagpur, Shenyang,

Ranchi, Zhengzhou, Seoul, Nanjing, Dubai, Manila, Kyoto,

Surat, Shymkent, Kuala Lumpur, Phnom Penh, Chittagong,

Yokohama, Davao City, Zhongshan, Bangkok, Busan, Chennai,

Kaohsiung, Khulna, Jakarta, Foshan, Taoyuan, Ankara,

Faisalabad, Tehran, Zunyi, Yekaterinburg, Xiamen, Kochi,

Istanbul, Hong Kong, Taipei, Wenzhou, Ho Chi Minh City,

Omsk, Almaty, Lahore, Osaka, Krasnoyarsk, Bandung, Incheon,

Xi'an, Dongguan, Rawalpindi, Fukuoka, Wuhan, Bengaluru,

Hefei, Shenzhen, Tianjin, Izmir, Lucknow, Vadodara, Medan,

Chelyabinsk, Hangzhou, Ahmedabad, Shanghai, Astana, Quezon

City, Shantou, Taichung, Hyderabad, Pune, Daegu, Dhaka,

Novosibirsk, Hanoi, New Taipei City, Caloocan, Kolkata,

Kawasaki, Riyadh, Baku, Quanzhou, Delhi, Mumbai, Tokyo,

Suzhou, Jeddah, Chongqing, Chengdu.

- Countries - Trinidad and Tobago, Antigua and Barbuda,

Chile, Ecuador, Belize, Haiti, Honduras, Cuba, Brazil,

Canada, Costa Rica, Dominican Republic, Grenada, El

Salvador, Uruguay, Suriname, Barbados, Dominica, Panama,

Saint Vincent and the Grenadines, Jamaica, Mexico, Paraguay,

Venezuela, Guyana, Bolivia, Argentina, United States of

America, Nicaragua, Colombia, Bahamas, Peru, Guatemala,

Saint Lucia.

- Cities - Columbus, Hermosillo, Montevideo, Maracaibo,

Campo Grande, Port-au-Prince, Quito, Houston, Managua,

Rosario, León, Córdoba, Bogotá, Mexico City, Cali, Santiago,

Jacksonville, Manaus, Natal, Indianapolis, Charlotte, Belo

Horizonte, Rio de Janeiro, Havana, Salvador, Campinas,

Phoenix, Dallas, Guayaquil, Medellín, Calgary, New York,

Philadelphia, Brasília, Austin, Tegucigalpa, São Luís,

Toronto, Denver, Chihuahua, Mérida, Puebla, Zapopan,

Barranquilla, Ciudad Guayana, Edmonton, Guarulhos,

Guadalajara, São Gonçalo, Barquisimeto, Duque de Caxias,

Recife, Santo Domingo, Santa Cruz, Tijuana, Trujillo, Ciudad

Juárez, Chicago, Lima, Monterrey, Ottawa, Buenos Aires, São

Paulo, Ecatepec, Valencia, San Antonio, Curitiba, San Jose,

Nezahualcóyotl, Porto Alegre, Fortaleza, San Diego, Caracas,

Goiânia, Acapulco, El Alto, Belém, Los Angeles, Guatemala

City, Montreal, San Francisco, Fort Worth.

- Countries - Vanuatu, Tonga, Solomon Islands,

Kiribati, Australia, Marshall Islands, Micronesia, Palau,

Tuvalu, Papua New Guinea, New Zealand, Nauru, Samoa, Fiji.

- Cities - Mandurah, Brisbane, Albury–Wodonga,

Toowoomba, Geelong, Suva, Hobart, Townsville, Dunedin,

Adelaide, Wellington, Christchurch, Tauranga, Central Coast,

Palmerston North, Perth, Melbourne, Darwin,

Newcastle–Maitland, Launceston, Sunshine Coast, Port

Moresby, Sydney, Nouméa, Hamilton, Lae, Cairns, Honolulu,

Ballarat, Papeete, Bendigo, Honiara, Gold Coast, Wollongong,

Canberra–Queanbeyan, Auckland.